- #1

Mark Merlo

- 2

- 0

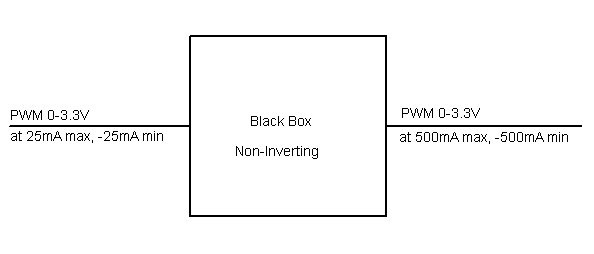

I would like to increase the maximum current that a PWM signal from a microcontroller can source/sink from +-25mA to +-500mA.

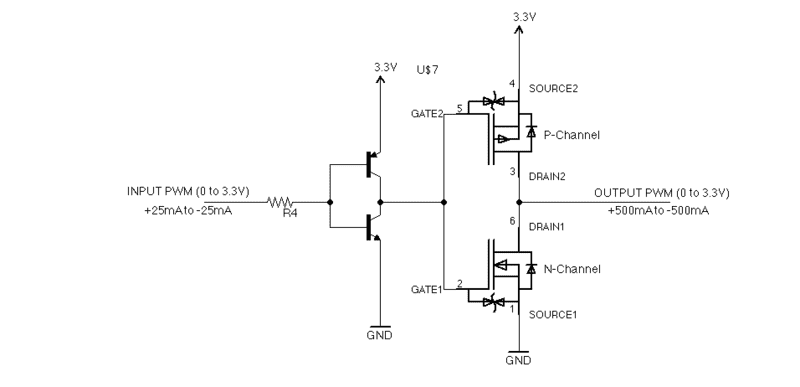

The output should have the same peak-to-peak voltage (0 to 3.3V) and should not be inverted (i.e. follows the input). The PWM frequency is ~30kHz. I have looked into using an active push-pull output but the only configuration I can find is inverting. Since the output needs to follow the input, I need to invert the input. I found this chip with complementary mosfets that looks like it would work for the output stage: http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=DMG1016V-7DICT-ND and this chip for the input BJT inverting stage: http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=MMDT2227MDICT-ND

Here is my proposed circuit:

The output stage mosfets have fairly small total gate charge of ~700pC each, so I think I could drive them directly with my microcontroller if I could find a non-inverting configuration.

So my questions are:

1. Will this circuit work?

2. Is there a single chip solution?

3. Is there a better circuit that would fit my needs (less components, cheaper, smaller footprint)?

4. Is there anything that I am missing? Diodes, resistors, etc?

Also, I do not have a specific load that I am driving, this is more of a generic output that can drive different load types. I would like to make this +-500mA source/sink PWM as similar to a uC output, but with larger current sourcing and sinking capacity.

Thanks for the help.

The output should have the same peak-to-peak voltage (0 to 3.3V) and should not be inverted (i.e. follows the input). The PWM frequency is ~30kHz. I have looked into using an active push-pull output but the only configuration I can find is inverting. Since the output needs to follow the input, I need to invert the input. I found this chip with complementary mosfets that looks like it would work for the output stage: http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=DMG1016V-7DICT-ND and this chip for the input BJT inverting stage: http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=MMDT2227MDICT-ND

Here is my proposed circuit:

The output stage mosfets have fairly small total gate charge of ~700pC each, so I think I could drive them directly with my microcontroller if I could find a non-inverting configuration.

So my questions are:

1. Will this circuit work?

2. Is there a single chip solution?

3. Is there a better circuit that would fit my needs (less components, cheaper, smaller footprint)?

4. Is there anything that I am missing? Diodes, resistors, etc?

Also, I do not have a specific load that I am driving, this is more of a generic output that can drive different load types. I would like to make this +-500mA source/sink PWM as similar to a uC output, but with larger current sourcing and sinking capacity.

Thanks for the help.

Attachments

Last edited by a moderator: