- #1

tirelessphoenix

- 16

- 4

- TL;DR Summary

- help with knob screws

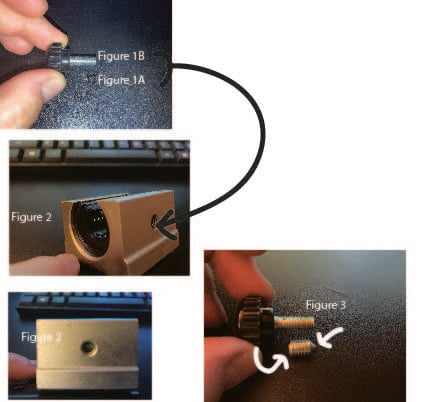

hi, I am having an issue with a knob-like screw. the original screw, seen in figure 1 A tigthens the hole in the figure 2 very good, but I tried to replace it with a knob like the one in Figure 1B, but it does not tighten right. both are an M6 type. I tried similar knobs like Figure 1B in sizes M5, M4 but are too thin. Does anyone know why Figure 1A screw tightens good but not the one shown in Figure1B? even both appear to be from same size and get into the whole ok?

Does anyone know if a knob of M6 size with a pointy ending like shown in Figure 3 exists? I don't know how to search it...what name to use...

thank you

TP

Does anyone know if a knob of M6 size with a pointy ending like shown in Figure 3 exists? I don't know how to search it...what name to use...

thank you

TP

Last edited by a moderator: